-40%

BESCUTTER PB SERIES 150T 10FT DELEM DA66T/DA53T CNC PRESS BRAKE

$ 38016

- Description

- Size Guide

Description

Powered byFrooition

bescutter

Q Series Galvo Fiber Laser Marker 20W-100W - Desktop Enclosed Type

Item Description

Product Description:

CNC Electro-hydraulic proportion press brake configuration:

CNC system:

Holland DA52S control 3+1 axes(Y1,Y2,X ,V )

◇

Hydraulic system:original Rexroth Germany

◇

Grating ruler: GIVI Italy

◇

Pump: Rexroth, Germany

◇

Electrical element Schneider.

◇

Servo motor and driver: DELTA TAIWAN

◇

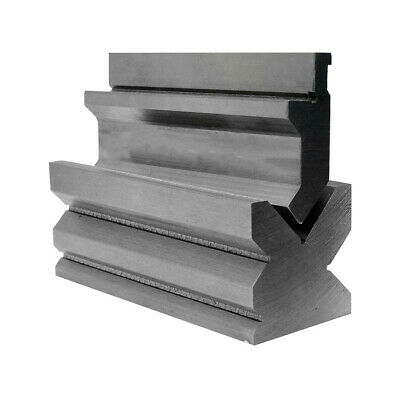

Toolings: upper tools fast clamping and with compensate, lower tool with multi V. Segmented tools according to your requirement.

◇

Seal ring: NOK Japan

◇

Front support with table, it can move right and left.

◇

Lower table mechanical crowning mechanism by controlled manual

◇

With safety side doors and back doors

◇

Hydraulic system with security valve, with spool position and manometer

◇

With All Security equipment monitored

◇

With the laser safety device.

Machine features

◇

Machine adopt w holly welding structure, the main parts annealing treatment, releasing internal stress.

◇

The frame and ram are processed at one time completely by heavy duty boring and milling machine.

◇

Big daylight, high ram speed

◇

Ram with fast clamping for up tooling, hydraulic crowning device on working table

◇

Advanced wholly back gauge, X axis, R axis, Z1 and Z2 with high speed, high precision.

◇

Standard configuration DA52S from Holland.

◇

Hydraulic system adopts Germany electric hydraulic proportional system.

Optional

◇

CNC controlling front supporter

◇

Multi axises control, Max. 16 axises

◇

Laser safe protection

◇

Bending angle automatic detection

◇

Hydraulic clamp for upper tool

◇

Mechanical crowning on working table

◇◇

Special toolsSpecial tools

CNC axis CNC axis function

◇

Y (Y1 Y2) axis: ram synchronous control axis, controlling bending depth and angle control. axis: ram synchronous control axis, controlling bending depth and angle control.

◇

X (X1 X2) axis: Control for back gauge front axis: Control for back gauge front--back stroke, using controlling bending flange size back stroke, using controlling bending flange size

◇

R (R1 R2) axis: Control for back gauge beam up axis: Control for back gauge beam up--down

◇

Z (Z1 Z2) axis: Controlled back gauge finger left axis: Controlled back gauge finger left--right movement.right movement.

◇

V axis: Working table auto--hydraulic crowning control

Simulation model engineering and optimization are with famous ANSYS non--linear software

Main Specifications

No

Name

Unit

Parameter

1

Nominal pressure

KN

630

2

Working table length

mm

3200

4

Center distance between uprights

mm

2600

5

Throat depth

mm

250

6

Ram stroke

mm

120

7

Max. open height

mm

380

8

Ram speed

No-loading speed

mm/s

200

Working speed

mm/s

11

Returning speed

mm/s

120

9

Motor

Power

KW

5.5

10

CNC system

Type

DA52S

CNC axes

axis

Y

1

,

Y

2

,

X,V

Quantity

1

1

11

Weight

KGS

5400

12

Back-gauge accuracy

mm

±0.05

㎜

13

X-axis Back-gauge Travel

mm

600

Back-gauge speed

Mm/s

300-500

14

Work-piece straightness

mm

0.25 /m

15

Bending angle accuracy

(ʹ)

±<0.5˚

16

Sliding Front Arms

Pics

2

17

Back-gauge Finger Block

Pics

4

18

Crowning System

Mechanical crowing

Safety configuration

19

Warning of high oil temperature

■Yes

□No

20

High oil pressure protection

■Yes

□No

21

Motor overload protection

■Yes

□No

22

Laser Safety Protection

■Yes

□No

23

Left & Right side protection

■Yes

□No

24

Electricity leakage protection

■Yes

□No

25

Safety Relay

■Yes

□No

26

Monitoring and Redundant valves

■Yes

□No

28

Safety standards

■UL

□No

More Items!

View more great items

30W Galvo Fiber Laser Engraver with Portable Head - Handheld Type

,000.00

Listed by

Frooition

Frooition | No-js Template | eBay design, eBay store design, eBay shop design, eBay template design, eBay listing design, eBay Listing Tool (ver:froo_no_js)